How to Specify Natural Leather Textiles for Commercial Construction Projects

Find centralized info on how to specify natural leather textiles for commercial construction projects. Information on different types of leather, leather processing, leather maintenance and care, and sustainability.

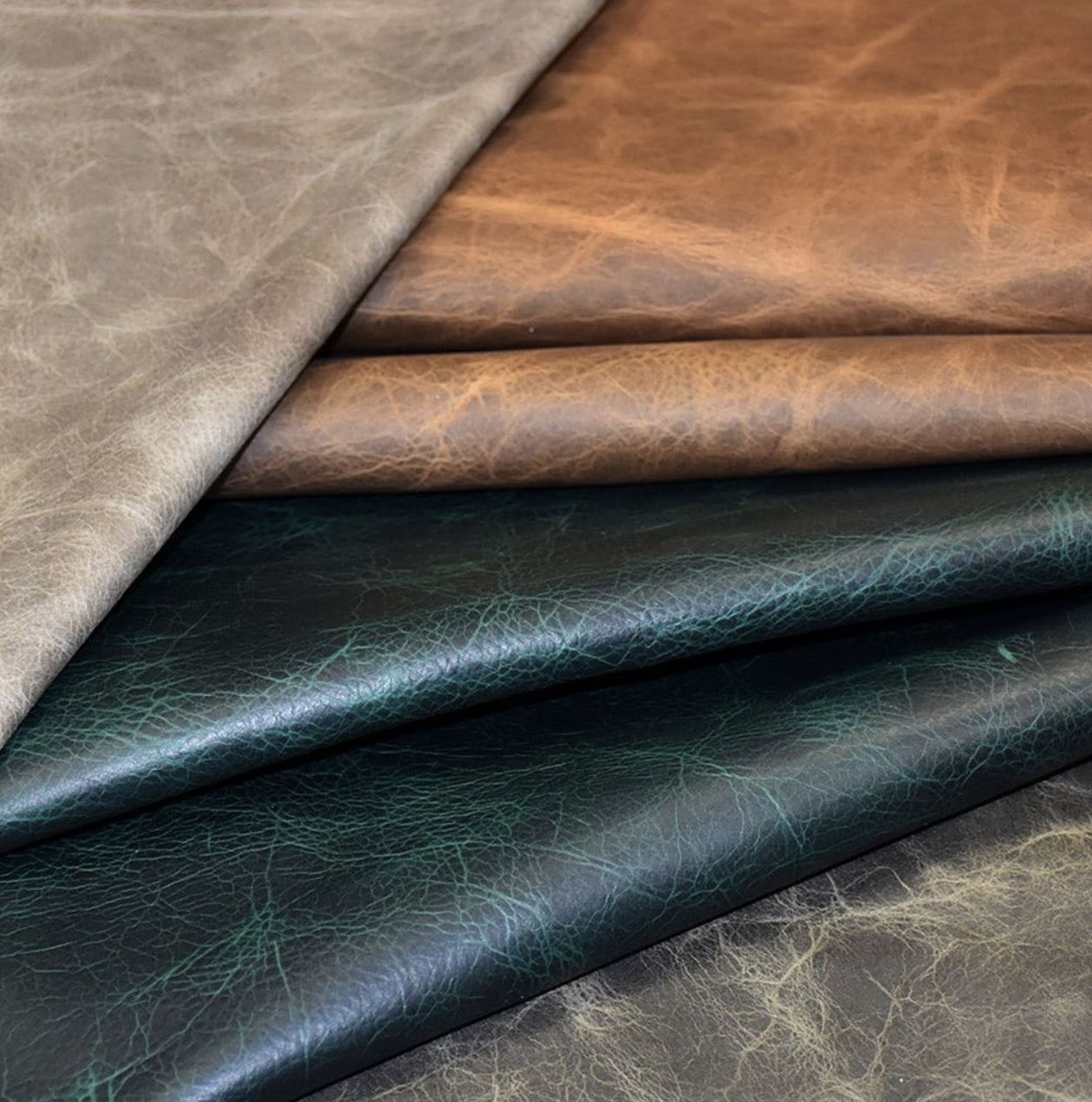

Images Courtesy of Moore & Giles

What is Leather?

Leather has been around for thousands of years. The oldest known leather object was discovered in 2010 in Armenia and dated to be about 5,500 years old, however the domestication of cattle about 10,500 years ago could mean humans have been using leather much longer! Simply put, leather is an animal hide (often cattle or sheep) or skin (smaller animals) that has been chemically preserved for use in clothing, furniture, small accessory items and more.

The earliest leathers were created by drying fresh animal skins in the sun, softened by pounding in animal fats, and preserved by salting and smoking. The chemical process today is called tanning, which turns a perishable material into a stable one. Tanning agents include vegetable tannins (from sources such as tree bark), mineral salts (such as chromium sulfate), and fish or animal oils. Once the hide is removed from the animal, it must be dehydrated prior to transportation to the tannery to prevent decay.

Some inherent aspects of natural leather can add character and beauty to the piece. The backbone will show a lighter stripe, it will take dyes differently than other parts of the hide, and the hairs lie differently creating a unique feature. Wrinkles can be used as a pattern or hidden with dye + pigment, however you want to avoid stretch marks as this indicates the animal grew too quickly. Some leathers will show insect bites and scratches. If they are not desired, they can be sanded away, however this reduces the overall strength of the leather. As long as the imperfections are healed, the leather will still be strong. Patina is natural darkening of the leather from oils, and can also soften the leather over time.

Images courtesy of Keleen Leathers

Leather Processing

Leather is made by removing the hide from the animal, prepping the hide with preservatives and removing moisture for transit to the tannery (which can be up to 30 days). The tanner will then purchase raw material: flawless leather is generally used for leather upholstery, and flawed leathers are used for fashion or products where smaller cuts will suffice. The usable area of a typical hide is 1 linear yard, or 18 square feet of leather. The rest is cut off at the edges and can be used for arm pads or other small items.

Once the leather is sorted, it is tanned. Chromium or Wet Blue chemicals create soft, pliable leather and is a one-day process. Vegetable tanning is a slower process, and is good for stiff leather products such as belts or saddles. Wet White is chrome free, however it uses other chemicals; this process is good for pastel leathers. Tanners can also mix processes, such as using Chromium and finishing with vegetable tannins for a stiff upholstery that is pliable yet firm. We’ll dive into the sustainability aspects of these chemicals later on.

After tanning, the leather is dyed. With dye only, you are still able to see the leather variation and natural texture. With dye + pigment, the leather is dyed in a vat of stain that soaks through the hide, then a light layer of pigment is added on top. This provides more visual consistency and wipeability. Dye + pigment resists fading from sunlight, and can be used in food service areas. Pigment only will wear poorly.

Next, the leather is dried in one of three ways. Air drying is simple and cost-effective. The leather is draped over a bar and takes two weeks to dry; there will be a small bit of shrinkage. Oven drying is a quicker process where leather is clipped to a perforated metal frame to minimize shrinkage, and takes only two hours to dry. Vacuum drying extracts moisture very quickly, constricts the grain, and smooths the surface nicely.

Once dried, the leather is then finished using various methods, depending on the desired end product.

Staking: the leather is massaged in a machine to make it softer and more pliable if the hide is too firm.

Ironing & plating applies heat and pressure to add a natural shine.

Milling or tumbling in a dryer softens and plumps natural grain leather without embossing.

Sanding is used to even out uneven surfaces and remove imperfections. Most leather is at least lightly sanded. If it is coarse sanded, this will remove the inherent strength and requires a lot of additional finishing and embossing.

Embossing prints a pattern over the natural leather to add texture and add enhanced aesthetic patterns.

Chemical finishing is pigmenting the leather by misting the hide in a chamber. A light coat of water-based pigments prevents over-coloration and looks less plastic than heavier pigments.

Oil & wax finishing is good for a distressed leather look, as scratches will show easily and patinas greatly over time.

Dyes & pigments: Leathers can be dyed in either aniline or semi-aniline dyes; aniline dye is a translucent, water-soluble synthetic dye without any insoluble pigments. The natural leather grain including all the markings, scars and wrinkles are emphasized. Semi-aniline dye contains a small amount of pigment, allowing the leather to show its natural characteristics while bringing more color consistency.

Topcoating adds a layer of extra protection that is cleanable, wipeable, and resistant to patina. Silicone or cellulose water-based topcoats are ideal as they won’t look overly-finished.

Images courtesy of Edelman Leather

Types of Leather

There are several types of leather, differentiated by how the hide is treated and processed. It’s easy to be fooled by the names, so read on to understand how to spot quality leathers by name.

Standard leather is minimally processed, and often includes natural imperfections such as brands, scratches and insect bites. Also called Full Grain or Natural Grain, it is strong, beautiful and will last for decades (50 years or more) if cared for properly. Minimally processed leather is the longest-wearing textile that will outlive polyurethanes and vinyls.

Nubuck is similar to standard leather; it is made from the outermost layer of a hide in which you can see the dots and grain intact, lightly sanded to give it a matte finish that is soft and supple to the touch. Nubuck will hold up just as well as standard leather in terms of longevity, however it may show staining more so avoid using this in food service areas.

Nubuck leather

Enhanced Leather is embossed over natural grain leather.

Suede is leather that has been split with a blade, exposing a deep layer of the hide and shows no grain, making it less durable than standard leather and is best used vertically or in residential projects. Split leather is another term for suede.

Hair hide is tanned like other leathers, but the hairs remain intact. Hair hides are great for floors as rugs, some upholstery, and vertical applications but are not great for seats as scooting can damage the hairs.

Genuine leather sounds great and is often seen in fashion, however it is actually one of the lowest quality natural leathers. It is made of several layers of low quality leftover leather (the parts of the animal hide lying between the top grain and suede) bonded together with glue, then painted to look like a better-quality leather. Bonded or recycled leather is affordable, but also low quality, created by gluing scraps of leather together to form one piece. You can spot a bonded leather sofa when you see the leather flaking off the seat; it may not even last a year before the breakdown of the material begins.

Bicast leather is made by taking a thin bottom layer of the hide, adding a polyurethane coating to make it glossy, and sometimes embossing to resemble full grain leather. It is affordable and often used in fashion and furniture pieces, but it is prone to cracking, scratching, and its appearance will degrade over time, unlike natural grain leather.

Corrected leather has been sanded and buffed to remove any natural imperfections and create a more consistent looking material. Top Grain leather sounds like “top shelf” quality, however it just means the top layer has been sanded or shaved off so that the leather is thinner and more workable for certain applications, and to provide a fresh surface for coatings to be applied. Both leathers are often imprinted with a grain pattern to look like full grain leather. These leathers will not patina and lose the softness of the natural grain. The bright side of these leathers is that they take scarred and imperfect leathers that may otherwise go to waste, and “correct” the appearance while retaining some of the natural quality of leather.

Image courtesy of Leather Research Laboratory

There are artificial leather products available, popular for their affordability, less labor-intensive production methods, and avoiding potential animal mistreatment in the leather industry. Artificial leathers will not patina with age like natural leather does. They are also much less durable than natural leather. Depending on your client and project type, a faux leather may be better for a project that requires some level of durability yet doesn’t need to last forever, whereas natural leather is best for clients that want to invest in the quality and longevity of their project.

Leather Care & Maintenance

To care for leathers and extend their lifetime, avoid cleaning with bleach or scrubbing aggressively. Wipe down with a leather-approved mild cleanser and a wet cloth. If stains are a concern for your project, use a dye + pigment leather, as the pigment will add protection. With dye-only, you will see dark marks where liquids have sat on the porous leather for a long time. You can also specify adding a light layer of silicone for extra protection. For deep stains, leather can be professionally cleaned. Don't be afraid to clean it - if it’s high quality leather, it is super durable! Leather is also not a food source for bacteria, and can be easily wiped down.

Always check with your local rep to ask whether leather is appropriate for your project’s specific application. Leather is not a good choice for healthcare settings, as harsh chemicals are used for cleaning. A leather with a light pigment protection makes it more wipeable, and keeps a consistent color over time; this is used in the SFO airport. Suedes are generally only appropriate for residential applications, or wrapped panels in commercial projects.

Sustainability

Leather is a renewable resource, and the most sustainable aspect of leather is its longevity. A minimally processed leather sourced from responsible tanneries will last a lifetime, keeping it out of the landfill for longer than other textiles. When selecting a leather, look for leathers sourced from Western Europe, as they generally have better veterinary practices, the animals are grass fed and not given growth hormones, and better cared for in general. Leathers sourced from the US and South America typically use growth hormones and show more branding and scratch marks from barbed wire. Maharam partners with tanneries in Italy, which are governed by strict environmental laws in Europe that regulate chromium saturation and water quality. Their leathers meet GreenGuard Gold by being minimally processed and therefore off-gassing less.

The processing and tanning of leather is controversial because it uses chemicals that can be potentially harmful to humans and the environment. Today, 80-95% of leathers are produced using Chrome or Wet Blue processing. Chrome III is a natural element that is not harmful in its natural state. It is found in many vegetables, fruits and meats, and is essential for the healthy operation of human vascular and metabolic systems. Current chrome-tanned leather contains between 4-5% of chrome III. During the processing, if the tannery uses poor practices, Chrome III can oxidize and convert into Chrome VI, which is a harmful chemical. Minimally processed leather is best - in European tanneries, they do not allow the leather to leave the tannery unless it has an extremely low level of Chrome VI (300ths of a percent).

Vegetable tanning sounds like a better option (and in ancient practices, it was) however today, the process uses the same chemicals (around 250!) as Wet Blue and Wet White. It also requires much more water. The leathers produced using this method are more stiff and less malleable than the Wet Blue and Wet White tanned leathers.

You may see products called “eco leather,” however these are typically made of bits of recycled leather mixed with a binder, turning it into a sheet composite material versus a true leather. “Eco” sounds great, however watch out for greenwashing, as this method uses lots of processing which nullifies the “sustainable” recycled aspect of this product.

The best thing you can do as a specifier of leather is to do your research on the leather and where it is sourced from, as responsible tanneries governed by environmental laws create the least amount of impact on the waterways and off-gassing, and produce the highest quality leather that will last a lifetime and do not contain harmful levels of chemicals.

Author

Maddy Gorman, NCIDQ | Interior Designer

Disclaimer

While we hope you find an incredible amount of value in this article, we surely haven’t been able to cover the broad swath of applications and particular circumstances that will come up on every project. We encourage and suggest that you should connect directly with your manufacturer’s rep regarding the specific specification needs of your project.

You can find your local manufacturer’s rep in the world’s largest commercial construction rep directory here. Grab their contact information, or send a message right on Source. Happy specifying!